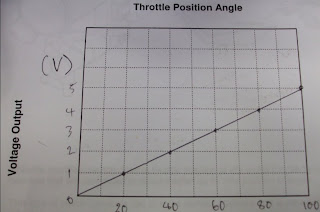

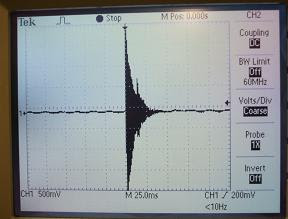

TPS (linear)

This TPS oscilliscope pattern is showing that the engine has started accelerating smoothly from idle. The TPS works by supplying a 5V reference to the potientiometer this read by a 'wiper' which connects with a different part of the potientiometer depending on how far the throttle pedal is depressed.

My theoretical fault is there is resistance in the earth wire.

My theoretical fault is there is resistance in the earth wire.For example the potientometer is 10k ohms, the resistance in the ground wire is 3k.

The throttle is at halfway.

Calculations.

R1=5000 R2=5000 R3=3000 RT=13k

5V/RT=0.000348 x R1=3.08 5-3.08=1.92

1.92/R2+R3=0.000385 x R2=1.925

1.92+1.92=3.84

5-3.84=1.16(R3)

So the signal sent to the ECU would be 3.84 for half throttle, but really the proper voltage for half throttle would be 2.5V.

As the ECU does not know any better it will adjust the air/fuel mix for a higher,roughly 2/3 throttle instead of half, which will cause the engine to run rich, which will effect performance and fuel efficiency.

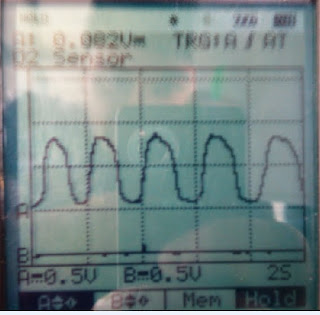

IAT

The IAT and ECT work the same way. Both the sensors are NTC thermistors, this means that when the temperature increases they will decrease in resistance. It can range from 24000 ohms to 200ohms, all depending on the temperature.

In this picture the IAT sensor is being warmed up, as this happens it is slowly decreasing in resistance.

The ECT and IAT work by voltage drop. There is a 5Vsupply, followed by set resistor which is in series with the sensor. The ECM is able to calculate the temperature by reading the Vd across the set resistor. The set resistor will change in Vd as the sensor warms up. When the sensor is cold the set resistor will have less resistance, giving it a low Vd. As the sensor warms up and the difference in resistance is reduced the Vd will decrease over the sensor and increase over the set resistor. As this continues the set resistance will become greater that the sensors resistance and will have a large Vd across it. Using this Vd the ECM can tell the temperature.

If there was a resistance in the ground wire this would cause a fault which would mean the Vd over the set resistor would not be accurate as it would b

e Vd across the extra resistance also.

eg.

4500 ohm set resistor, and the temperature is 40C, so around 1100 ohms. VS=5V

4500(R1)+1100(R2)+400(R3)=6000(RT)

Vs/RT=0.000833

R1 x 0.000833=3.74

Vs-3.74=1.26

1.26/R2+R3=0.00084

R2 x 0.00084=0.924

3.74+0.924=0.336

R3 creates a 0.336 Vd.

So the set resistor is Vd 3.74 but it should be 4.014(did the same calculations for a normal reading), this will give the ECM a inaccurate reading.

ECT

The IAT and ECT work the same way. Both the sensors are NTC thermistors, this means that when the temperature increases they will decrease in resistance. It can range from 24000 ohms to 200 ohms, all depending on the temperature.

On this ECT sensor, at 20C it was around 2.7k ohms and as it warmed up the temperature reached 100C at 200 ohms.

On this ECT sensor, at 20C it was around 2.7k ohms and as it warmed up the temperature reached 100C at 200 ohms.If the set resistor (R1) is 20k ohms, the sensor is at 70C which is 400 ohm(R2)

There is a resistance in the ground wire of 8k ohms(R3).

R1+R2+R3=28.4k ohms (RT)

5V/28.4k=0.000176 x R1=3.52Vd

5-3.52=1.48

1.48/R2+R3=0.000176 x R2=0.7+3.52=3.59

5-3.59=1.41R3

As the voltage drop is lower of R1 than it should be, the ECM receives the wrong reading which effects the performance of the engine as they ECM will think its colder than it really is.

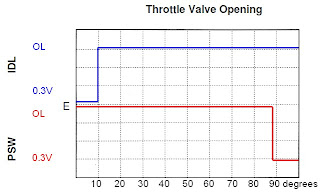

MAP

This oscilliscope pattern is showing me that there is little pressure going through the intake manifold. So that means the engine is idling, and at WOT the engine would show 5V as the pressure increases. The way the voltage is increased by pressure is that there is a reference chamber of pressure, a known pressure. This is seperated by a silicon chip, to the air pressure of the intake manifold. When the pressure increases the silicon chip changes its resistance which effects the output voltage.

Calculations

R1=14k ohms

R2=7k ohms

R3=6k ohms

R4=10k ohms

R5=19k ohms

RIN=2k ohms

RF=5k ohms

A= R1+R2+R5=RT1 (40K)

5V/40K=0.000125 x R1=1.75Vd at R1

5V-1.75V=3.25 at point A

B=R3+R4+R5=RT2(35k)

5V/35k=0.000125 x R4=1.428exp-4 x R4=1.428Vd at R4

5V-1.428=3.572V at point B

RIN

B/Rin=0.001786

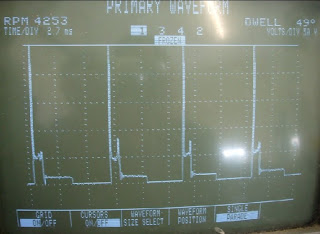

MAF

The MAF sensor is used to measure the amount of air(mass).

At A the engine is accelerating hard WOT, increasing the mass airflow.

At B the car is decelerating to about half throttle.

At C the car is accelerating smoothly up to WOT.

At D the car is off the throttle, but the engine is still slowing down which is still drawing air in.

At E throttle is blipped increasing the air flow for a split second.

Calculations

Platinum wire=R1=34K Ohms

B-earth=R2=15k Ohms

Bad earth=R3=58K Ohms

RT=107K Ohms

5V/RT=4.672exp-5

R1 x 4.672exp-5=1.588

5-1.588=3.412V output at B

As there is a big resistance in the earth circuit, it draws voltage away from the lessers resistors, R1 and R2 and uses most of the voltage over R3. This effects the voltage at B as there would be less Vd across R1 as the voltage is needed down at R3. So there would be a higher reading at B.

V.

V.